ThinProbe PROCESS REFRACTOMETER

Measures concentrations of solutions to within 0.1% accuracy

Accuracy level maintained even with particles, fibers, bubbles and color

How ThinProbe Works, The Refractometer principle

The critical angle of total reflection splits the incident beam on the prism surface into two beams, one totally reflected and the other refracted into the product. Then an optical image is projected on the digital CMOS sensor with a bright reflected zone and a shadow. The position of the shadow edge indicates the concentration of the product.

These optics produce an accuracy of ±0.1% concentration which corresponds to the accepted Cargille standard liquids of ±0.0002 RI.

Better Accuracy with ThinProbe´s Midstream Measurements

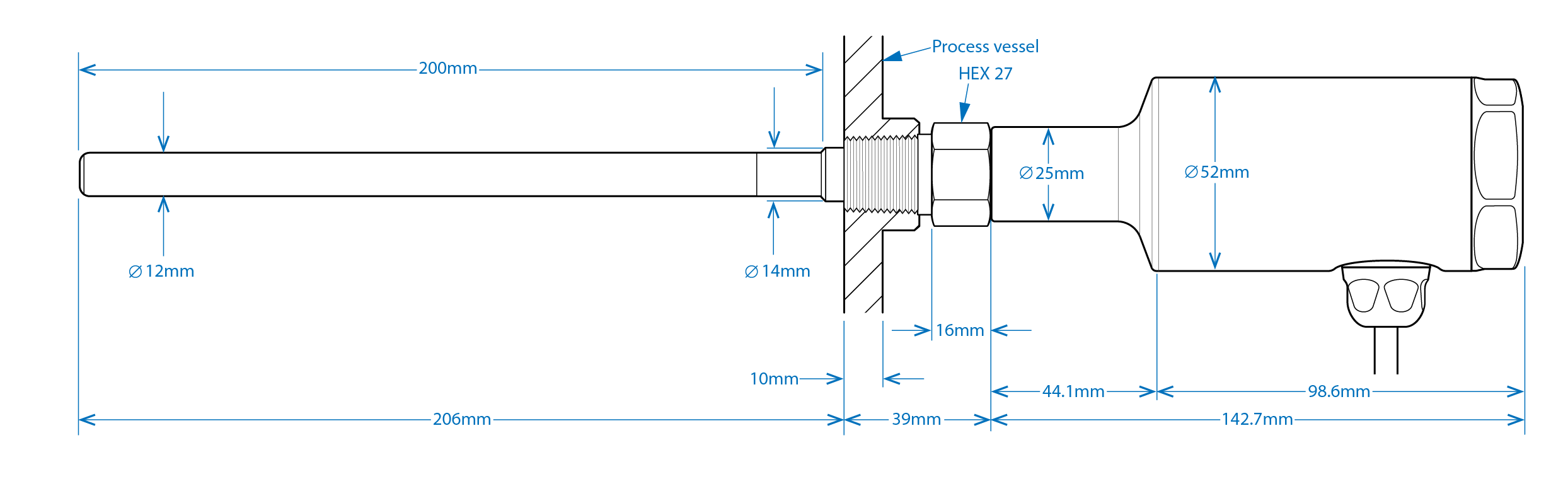

Measurements should be taken midstream to obtain the most reliable and accurate readings. Readings taken at the pipe wall suffer inaccuracies due to friction-induced flow sluggishness at the pipe wall. The ThinProbe´s midstream readings provide faster and more representative measurements.

The ThinProbe also measures temperature. The concentration reading must be temperature compensated. The reading of the concentration is optical and therefore instantaneous but the temperature has a time delay. It is possible to claim ±0.1 accuracy if the process temperature keeps constant. if the temperature varies, a fast measurement of temperature is necessary to keep full accuracy.

ThinProbe´s thin wall thermowell provides faster temperature response times

The ThinProbe gives a temperature reading along with the concentration. It measures temperature as fast as a standard thin-walled Thermowell.

Typical 12mm Thermowells

Temperature measurements are normally taken midstream with the temperature sensing element protected in a 12mm Thermowell. Temperature measurement is never at the pipe wall

ThinProbe should be installed as ASME PTC 19.3" at a pipe elbow with the tip facing upstream. This reinforces the unmatched fast response of the ThinProbe. The faster the feedback, the better the control. The temperature reading is swift and exact, as the probe is immersed in the main stream. The prism surface keeps clean as it is washed by the Flow, and the probe tip doesn’t cool the liquid.

ThinProbe is even effective at measuring dirty and sticky liquids. For these, the ThinProbe is equipped with a prism wash nozzle. And, uses either water, steam or high pressure water. Compared to other types of instruments, the ThinProbe´s small, flat polished surface is kept clean. Therefore it can handle clinging products like starch and beer wort.

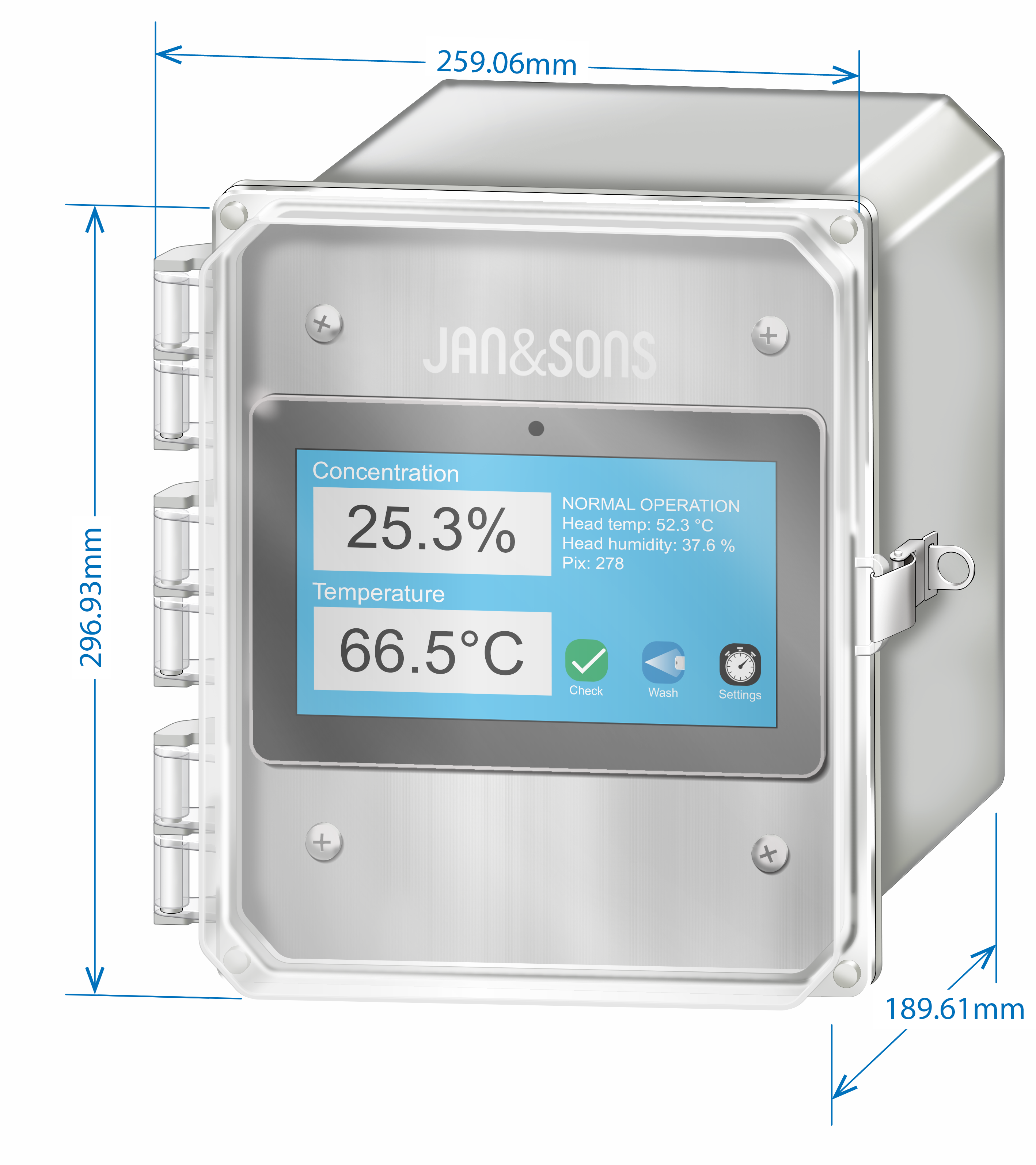

The Indicating Transmitter supports a refractometer by:

- 2 x 4-20 mA outputs for concentration % and temperature °C.

- 2 x relay outputs that drive the wash and preconditioning valves.

- Ethernet output

One Indicating Transmitter supports two refractometers.

CRYSTALLIZER

In a crystallizer, there is no need for prism wash. The crystal abrasion keeps the prism clean. The ThinProbe measures the liquid concentration independent of the amount of crystals, as the measurement is from the wetted prism surface. The supersaturation of the liquid determines the speed of the crystallization.

FERMENTER

Prism wash is required in a fermenter. In a fermenter, the ThinProbe controls the concentration of the feed to optimize the growth rate of the product. As the liquid is fouling, a prism wash is required.

In a batch process, Prism wash cannot be done directly since wash liquid can accumulate in the solution. Instead, an Exner probe housing is used, where the probe tip is withdrawn into a separate chamber for prism wash thereby preserving the process concentration.

The recommended mounting in a pipe is at an angle against the flow.

A 12 mm diameter probe is the pharma standard for all sensors, such as for pH and turbidity. Hence, ThinProbe can be used together with all pharma fittings.

With other probes, Flow Forces can cause measurement error since they will bend the refractometer probe. This makes other probe refractometers flow sensitive, because bending causes an offset Δ on the sensor. In the illustration, bending is exaggerated for clarity, but even an offset Δ = 10 μm will cause a one-pixel position error on the CCD.

In contrast, flow induced bending does not influence ThinProbe measurements, because the device uses an image conduit to transport the optical image to the CMOS sensor. The image conduit is a bundle of optical fibers that transports the pixels one by one, eliminating any offset caused by bending.

ThinProbe has a compact and robust optics system based on a 512-pixel CMOS sensor, instead of a cumbersome 3648-pixel CCD. When you have enough pixels, the intermediate points can be precisely calculated, grey line. The powerful Savitzky-Golay statistical method then treats the optical image as a continuous curve, independent of the number of pixels. This method is applied to the optical image to localize the abrupt change at the shadow line.

The Savitzky-Golay method produces a family of curves whose peaks mark the shadow line with unmatched precision. In fact, the Savitzky-Golay method utilizes the data so efficiently that if you use only half the pixels (256), precision will still not suffer. The shapes of the curves are not in uenced by the form of the optical image.

The result of the test with Cargille standard RI liquids produces the refractive index at 25°C as function of pixels. We now have a good measurement of refractive index. The measurement must, however, be converted to a concentration percentage. From over 150 years of precise laboratory measurements with Abbe refractometers, we know how concentrations depend on RI at 20°C. For other temperatures, the Lorenz-Lorentz equation works for stable molecules, but not at hydration or dissociation. In these cases, the practical method is to collect data from actual in-line measurements and calculate the temperature compensation factors accordingly.

ThinProbe 100

ThinProbe with prism wash nozzle

ThinProbe 200

ThinProbe Exner

SPECIFICATIONS:

• Refractive Index range: Full range, nD 1.3200...1.5300 (corresponds to 0... 100% b.w.)

• Accuracy: Refractive index nD ± 0.0002 (corresponds typically to ± 0.1% by weight)

• Speed of response: 1s undamped, damping time selectable up to 5 min

• Calibration: With Cargille standard R.I. liquids over full range of nD 1.3160... 1.5300

• Digital measurement: CMOS linear detector

• Light source: Light emitting diode (LED), 589 nm wavelength, sodium D-line

• Temperature sensor: Pt-1000, linearization according to IEC 751

• Temperature compensation: Automatic, digital compensation

• Instrument verification: With NIST traceable Cargille standard R.I. liquids

• Ambient temperature: Sensor: max. 45°C (113°F), min. -20°C (-4°F) | Indicating transmitter: max. 50°C (122°), min. 0°(32°F)

• Process connection: NPT 1/2” | Triclamp - DIN 32676 Flange size = 34 | Exner EXtract 830M retractable probe housing

• Process pressure: up to 25 bar (350 psi)

• Process temperature: -20°C... 150°C (-4 °F... 302°F)

• Process wetted parts, standard: AISI 316L stainless steel, prism spinel, prism gaskets modi ed PTFE (Te on)

• Sensor protection class: IP67, Nema 4X

• Sensor weight: 0.6 kg